![]()

Forming Dovetail Double Deck |

Rigidity is the key to rough forming and Slater Tools gives you this and adds a double deck position. |

Roll Supports & Steady Rest Holders    |

|

Flat Form Tool Holder |

Rigidity is the key to rough forming, and Slater gives you this plus the double deck for mounting an additional application.Configuration based on machine make and model |

| Shaving Dovetail Tool Holder

|

On any machine in good condition, shaving will produce diameters which are round, and on size within +/- .0005.Contours can be produced which otherwise would be possible only by tracing. By its nature, shaving can almost always be completed in less revolutions than an end-working operation; hence shaving seldom is the limiter on cycle time. Shaving also has its built-in diameter controls; it does not rely on exact cross slide stroke length for accuracy, and to a certain extent, it can compensate for index or spindle errors. If holders, and the machines, are in good condition, and if properly designed, correctly ground tools are used at appropriate feeds and speeds, shaving gives minimum trouble. |

| Support Shaving Endslide

|

|

| Skiving Tool Holder

|

Skiving tool holders from Slater Tools are for single & multiple spindle automatics and turret lathes. You can now make your toughest cuts within seconds. |

Swing Arm |

|

Vertical Slide |

|

| Milling Rotating Attachment

|

Revolving straddle type for machines without spindle stopping.

|

| Turning Roll Turner

|

|

Polygon Turning Cross-Slide |

This Polygon Toolbox was designed for the purpose of turning hexagonal, octagonal, square, or any irregular shapes with its capacity, quickly and free from burrs, and eliminating the necessity for subsequent milling operations Boxes have since been developed to suit most types of turret and automatic lathes, and other interesting developments include the boring of polygon shaped holes to afford perfect mating to external shapes produced on the same box. |

| Polygon Turning End-Slide

|

2This Polygon Toolbox was designed for the purpose of turning hexagonal, octagonal, square, or any irregular shapes with its capacity, quickly and free from burrs, and eliminating the necessity for subsequent milling operations. Boxes have since been developed to suit most types of turret and automatic lathes, and other interesting developments include the boring of polygon shaped holes to afford perfect mating to external shapes produced on the same box. |

Turning Knee Plain, Reversible, Angular 45   |

|

| Boring Bar Holder

|

|

Center Live Retractable |

|

Cut-Off Blade Holder |

|

| Forming Bridge Double Deck

|

|

Recess Rotating Attachment |

When grooves must be formed deep within a hole their shape, size and concentricity often can be improved through the use of a revolving recess milling attachment. The holder itself amounts to a wedge-type drawback recessing attachment in which the tool is held in a spindle mounted on precision bearings in such a manner that it can be driven by a splined shaft from the screw machine’s gear box, as an accelerated drill, or die head would be. |

Rotary Broaching Orientation Dog |

This unique tool is used for orientation or alignment of broach formed to workpiece location. Take control of positioning this amazing application! |

| Forming Circular Double-Deck

|

Get Maximum Performance of your Mutiple Spindle Automatic with the use of Slater Tools series of Double Deck Tool! |

Rotary Broaching Attachment |

It is synchronized (1:1 ratio) with the spindle by means of a spline shaft and pick-off gear. This attachment has several advantages. It eliminates any twisting of the form and skidding on the work piece chamfer. It also increases the broach tool life and deeper forms can be obtained. Slater Tools offers a variety of attachment sizes for internal and external work.This attachment is available for use on these multi-spindle machines:

|

Recess Clamp Type Tool Holder |

Heavy-duty clamp model mounts directly on tool slide of machine. Picks up shere shank-type holder leaves off. Greater rigidity on heavier cuts with increased accuracy.Use of a draw bar attachment or stop rod with roll used to actuate recess tool holder. Positive endwise location to tool is made easy with adjustment through the hex nuts. |

Recess Shank Type Tool Holder |

These tool holders are ruggedly built for wide and accurate recessing. Except for the shank, they are hardened and ground throughout. Tapered gib allows accurate adjustment for wear. Round shank type recess tool holders may be used for internal forming, as well as grooving and chamfering. Round shank type recess tool holder may also be used for undercuts which cannot be reached by a standard tool working from the main tool slide. The holder may be actuated in several ways, one by a draw bar anchored to a bracket built on to the cross slide or frame of the machine, or by a stop rod in the holder contacting a turned diameter of the part piece. |

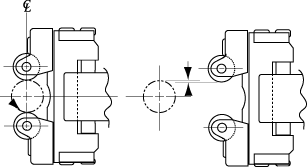

| Knurling and Burnishing

|

You get precision knurling and burnishing when you use Slater Tools Knurling Tool holders, because you are getting features and production advantages not found in any other tool holders.These knurl tool holders are of the straddle-type, which tangentially feeds to center from the cross slide of the automatic or turret lathe.

Adapter blocks allow the holders to fit most makes, models, and size of machines. Holder assemblies are designed to compensate for any slight misalignment with centerline of the spindle. Size control is made easy through simultaneous adjusting of both knurl roll holders. Slater Tools straddle-type knurl holders increase machine life and save on setup time and maintenance costs. No extra expense for tooling, these tool holders use standard, commercially available knurl rolls! |