Shaving

Shaving is the ideal method of improving part accuracy, concentricity and finish. Our shave tool holders are designed to eliminate both spindle index error and slide infeed error- the two most common causes of part variance on a production screw machine. Our original patented pin-style shave tool holder is available in a wide variety of sizes. For very tight tolerances, consider double shaving. While a single pass will hold ± .0005″ on the diameter, double shaving can double that accuracy. Shaving is always recommended prior to thread rolling or knurling.

Shaving is the ideal method of improving part accuracy, concentricity and finish. Our shave tool holders are designed to eliminate both spindle index error and slide infeed error- the two most common causes of part variance on a production screw machine. Our original patented pin-style shave tool holder is available in a wide variety of sizes. For very tight tolerances, consider double shaving. While a single pass will hold ± .0005″ on the diameter, double shaving can double that accuracy. Shaving is always recommended prior to thread rolling or knurling.

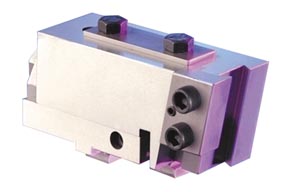

Dovetail Holder

Dovetail form tool holders are available in several styles: Standard (no adjustments), Adjustable (adjustable infeed) and T-series (adjustable infeed and zero-backlash taper adjustment). Our holders are engineered to be robust and reliable. Once setup, they hold their position and will last and last …

Dovetail form tool holders are available in several styles: Standard (no adjustments), Adjustable (adjustable infeed) and T-series (adjustable infeed and zero-backlash taper adjustment). Our holders are engineered to be robust and reliable. Once setup, they hold their position and will last and last …

Recess Attachments

Shank Style Recess Tool Holders are ideal for light and medium undercutting of the work piece, are quick to setup and can be used on many different machines.

Shank Style Recess Tool Holders are ideal for light and medium undercutting of the work piece, are quick to setup and can be used on many different machines.

Key Benefits

- Economical and efficient.

- Springs are fully shielded and cannot pack with chips, providing reliable operation.

- Hardened and precision ground bearing surfaces.

- Adjustable gib for precision fit and long life.

- Quick and easy tool change

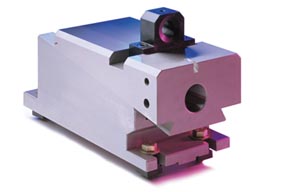

Clamp Style Recess Tool Holders are engineered for heavier and wider cuts than shank style holders, even in difficult materials. This design clamps directly to the main tool slide, which increases stiffness and accuracy.

Clamp Style Recess Tool Holders are engineered for heavier and wider cuts than shank style holders, even in difficult materials. This design clamps directly to the main tool slide, which increases stiffness and accuracy.

Key Benefits

- Both heavy and wide cuts, profiling.

- Through-tool coolant capability.

- Springs are fully shielded and cannot pack with chips, providing reliable operation.

- Hardened and precision ground bearing surfaces.

- Adjustable gib for precision fit and long life.

- Quick and easy tool change.

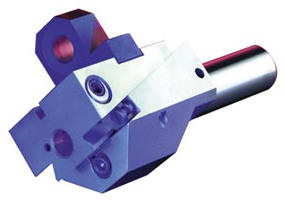

Recess Milling Attachments are engineered to mill heavy, wide profiles in difficult materials. This holder solves the chip evacuation problem which can occur with a stationary tool. The profiling cutter rotates opposite the spindle to produce fine chips which are easily evacuated from the interior of the part. Because the tool cuts more freely, most taper problems are eliminated as well. heavier and wider cuts than shank style holders, even in difficult materials. This design clamps directly to the main tool slide, which increases stiffness and accuracy.

Recess Milling Attachments are engineered to mill heavy, wide profiles in difficult materials. This holder solves the chip evacuation problem which can occur with a stationary tool. The profiling cutter rotates opposite the spindle to produce fine chips which are easily evacuated from the interior of the part. Because the tool cuts more freely, most taper problems are eliminated as well. heavier and wider cuts than shank style holders, even in difficult materials. This design clamps directly to the main tool slide, which increases stiffness and accuracy.

Key Benefits

- Eliminates chip problems by creating fine, easily evacuated chips.

- Superior part accuracy and finish.

- Through-tool coolant capability.

- Springs are fully shielded and cannot pack with chips, providing reliable operation.

- Hardened and precision ground bearing surfaces.

- Adjustable gib for precision fit and long life.

- Erickson type spindle is standard, Weldon style spindle is optional.

Burnishing

Burnishing holders (also called 3 roll supports) are available in clamp styles and shank styles (shown). Clamp styles have increased capacity through the bore, while shank style holders can hold a round shank tool for multiple uses on the end of the part.

Burnishing holders (also called 3 roll supports) are available in clamp styles and shank styles (shown). Clamp styles have increased capacity through the bore, while shank style holders can hold a round shank tool for multiple uses on the end of the part.

Our burnishing holders feature simple, independent adjustment of each roll holder block. Their rugged design means that your setup stays precise throughout the production run.

Hex Master Broaching

Save time and money by machining a high-quality hex into your steel, brass or aluminum part in seconds! HexMaster™ works like a high speed chisel to cut a hex into your pre-drilled pilot hole. Set-up is as easy as centering the hex broaching tool on the work ..

Save time and money by machining a high-quality hex into your steel, brass or aluminum part in seconds! HexMaster™ works like a high speed chisel to cut a hex into your pre-drilled pilot hole. Set-up is as easy as centering the hex broaching tool on the work ..

Key Benefits

- Oversized Bearings designed for durability and long-life

- Unique tool knock-out hole gets you running again quickly in case of a broken tool

- Advanced design allows us to offer this Best-in-Quality holder at rock bottom prices!

- Tooling widely available

Skiving

Skiving is similar to shaving in that the tool passes off of centerline, and is fed through and past the part. The skiving inherently corrects for some of the infeed error, but does not correct for machine index error. Because the skive tool is angled on its face, the cut begins at one side of the tool and proceeds to the other side of the tool as the holder is fed into the part. The portion of the tool which has already cut the part tends to act as a support for the remainder of the cut. For medium accuracy part with a tolerance of ±.002″ on the diameter, skiving is the fastest finishing solution. Feed rates start at two t o three times that of forming or shaving. Quickly removes up to 1/2 of stock diameter.

Skiving is similar to shaving in that the tool passes off of centerline, and is fed through and past the part. The skiving inherently corrects for some of the infeed error, but does not correct for machine index error. Because the skive tool is angled on its face, the cut begins at one side of the tool and proceeds to the other side of the tool as the holder is fed into the part. The portion of the tool which has already cut the part tends to act as a support for the remainder of the cut. For medium accuracy part with a tolerance of ±.002″ on the diameter, skiving is the fastest finishing solution. Feed rates start at two t o three times that of forming or shaving. Quickly removes up to 1/2 of stock diameter.

Key Benefits

- More accurate and faster than dovetail or circular form tool holders

- Good finish

- Tool provides some limited support during the cut

- Sizes for a wide variety of machines

- 1 degree top relief built-into the holder

- Stock removal limited to 1/2 of part diameter

Work Supports

Our two roll forming supports will support your work in even the toughest conditions. Using a work support is the best, most economical way to make consistent parts whenever the part length or configuration allow the part to deflect during machining.

Our two roll forming supports will support your work in even the toughest conditions. Using a work support is the best, most economical way to make consistent parts whenever the part length or configuration allow the part to deflect during machining.

Two Roll (Forming) Supports improve finish and accuracy. Engineered for ruggedness and ease of use, these economical holders are available for a wide variety of screw machines.

Key Benefits

- Easy to use, robust design holds location throughout production run.

- Rolls adjust independently for precise alignment.

- Available with standard rolls, wide rolls and tapered rolls (allowing closer adjustment of the roll to the part).

Our single roll shaving support will keep your work from deflecting while the diameter is shaved. Using a work support is the best, most economical way to make consistent parts whenever the part length or configuration allow the part to deflect during machining.

Our single roll shaving support will keep your work from deflecting while the diameter is shaved. Using a work support is the best, most economical way to make consistent parts whenever the part length or configuration allow the part to deflect during machining.

Shaving supports are easy to use, economical and available for a wide variety of screw machines.

Key Benefits

- Robust design holds location throughout production run

- Roll is easily adjusted for precise alignment

- Available with standard rolls, wide rolls and tapered rolls (allowing closer adjustment of the roll to the part)