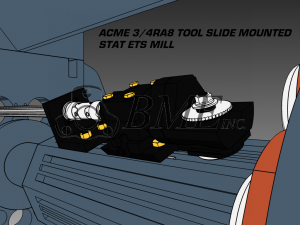

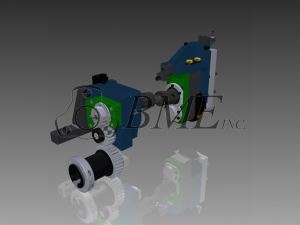

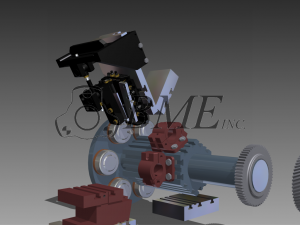

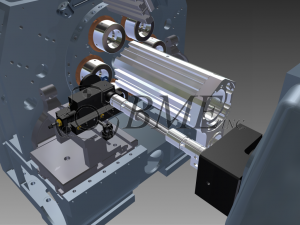

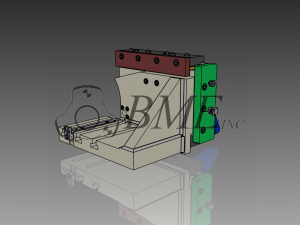

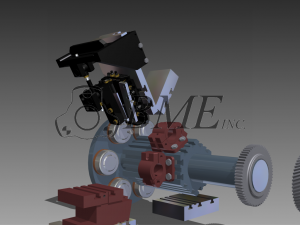

Stationary End Tool Slide (ETS) Milling Attachments

These are a few of the newest attachments we’ve been working on. Click each picture to see the 3D model assembly! |

|

|

|

|

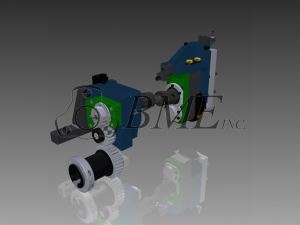

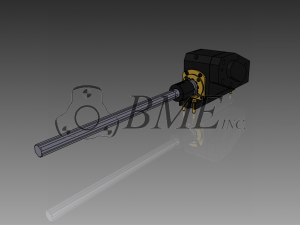

Davenport Polygon

We are now offering a polygon attachment for your Davenport automatic screw machine. Like our other polygon attachments, it can easily be converted to a threadmilling attachment. Just change the gears! Depicted above, our Davenport Polygon/Threadmill is a revolutionary development as it is the first of its kind to be produced for the Davenport. It is easy to install and comes with unparalleled support. Tooling is available! Call us today for pricing and delivery! |

|

|

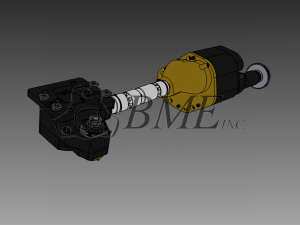

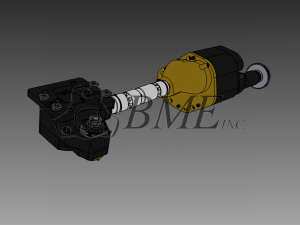

Synchronized Cross Drilling

Synchronized cross drilling attachments drill cross holes in screw machine parts while the spindle is turning without the spindle stopping. They can drill multiple holes at the same time, from 1 to 4 holes 90 degrees apart. The drills can also be designed to put chamfers on the part at the same time. Attachments feature a quick change drill cap assembly that allows tool changes in less than two minutes. It also features a high pressure coolant system that flushes out chips. Mounted on the main tool slide; it has independent adjustable drills that are easy to adjust.

Synchronous Cross Drill [Tool Holders & Attachments] |

|

|

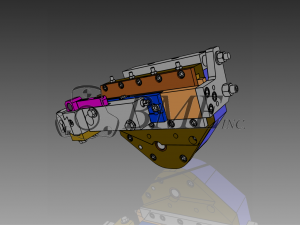

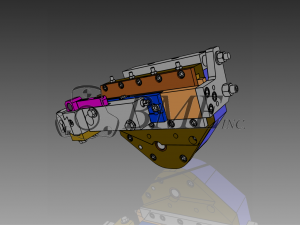

Face Grooving Attachment

This is our Face Grooving Attachment. This attachment will allow you to cut a face groove on either side of a shoulder from the cross slide on your multi-spindle machine. Call us for a quote today! |

|

|

Flat Generating Polygon Turning

Polygon attachments are mounted on the cross slide or main tool slide and cut flats with a cutter that is synced to the part. This is called flat generating. One flat or multiple flats can be made with different ratios and cutters. For example, to create the six flats on a hexagonal part such as a hex bolt, you would use a cutter with three inserts spaced equally 120 degrees apart at a ratio of 2:1. The polygon attachment’s cutter is spinning at twice the rate of the part in your screw machine. Watch the video below for a demonstration of this process.Thread milling attachments use an advanced spindle technology to achieve the lowest possible run out. They also have a base plate system that allows exact taper adjustment which allows this attachment to be mounted on older machines that might be worn or out of square. Thread milling in steel can be achieved using carbide cutters, great for very narrow threads and non-ferrous materials that do not roll well.

Flat Generating Brochure |

|

|

Synchronized Cross Stamping

Are you stamping your parts in a second operation? Save time and money and invest in a synchronized cross stamping attachment! This attachment goes right on the cross slide of your Acme Gridley Machine. It uses the same transmission as our polygon and threadmill attachments. Heavy Duty construction and machined and serviced here in the USA! |

|

|

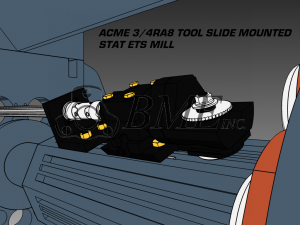

Stationary Cross Slide Milling

This is an example of an attachment that we engineered specifically to meet a customer’s needs. This a stationary cross slide mill on a 3/4″ RA8 Acme Gridley in the 5th position. It uses a different transmission box than our other attachments and makes an isolated cut parallel to the part. If you need an engineering solution, give us a call! We stand behind our products and will build any attachment to suit your needs! |

|

|

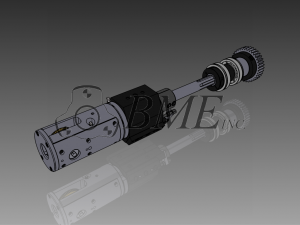

Rotary Recess Attachments

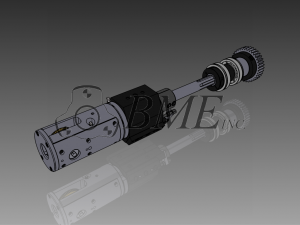

These are our high-pressure coolant thru rotary recess attachments. We can make these for your Acme Gridley, Wickman, or New Britain automatics. The attachments have high-pressure coolant through the spindle. This makes the rotary recess attachment very easy to integrate into an existing coolant system. Hardened and blackened steel, driven by the machine’s existing gear train. Installation available! Manufactured and serviced in the USA!

Rotary Recess Attachment Catalog Page |

|

|

Shave Tool Holders

These are former Empire shave holders. Looking for someone to produce or service one of these attachments? Look no further. We keep replacement parts for these holders in stock and on the shelf. We have the most common machine sizes ready to produce. Like all of our products, we stand behind these attachments. They are CNC machined at our shop in Michigan. If you ever need a part replaced, right down to the smallest set screw, we have it. Installation is available! Made and serviced in the USA!

Shave Tool Holder Catalog Page |

|

|

Pickoff and Back Finish Attachments

These are standard National Acme pickoff attachments. They are manufactured to Acme specifications and made from high quality materials. The slides are hardened and ground. Pneumatic packages are available. We can engineer a pickoff or back finish for your custom application! Free Installation included with purchase of entire pickoff/backfinish assembly! Training on site!

Pickoff and Back Finish Catalog Page |

|

|

Back Finish Slide Assemblies

Complete backfinish assemblies for Acmes, tool blocks heat-treated and precision ground, heat-treated gears. Replaces standard Acme, competitively priced, installation available, custom tool blocks. Trade-In available! Special engineering for any type of part! Training on-site always available! |

|

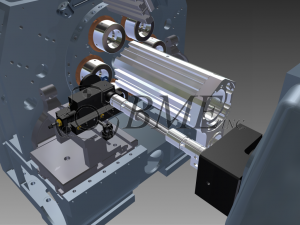

Synchronized Slotting and Milling Attachments

Fit most multiple spindle automatics, heavy-duty all bearing construction, 1/2” cutter width, easy installation. Hardened and ground components. Face plate system allows support bushings. Robust dual supported cutter shaft, high pressure coolant ports. Heat-Treat gear system, Tramble way plate system, no boring required. Attachment Drive Unit is included. Attachment Top RPM = Machine Top RPM.

Synchronous Mill Catalog Page |

|

|

Shelf Slide Attachments

We have new shelf slides for Acmes. Slides are ground and square. Slides are hand-scraped into bases for maximum contact area. Extra lubrication points for longevity. Slides are manufactured to National Acme Specifications. Replacement parts available. We also offer rebuilding service for your existing slides. Trade in your worn out slides! Installation available!

Shelf Slide Catalog Page |

|

|

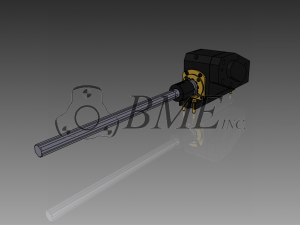

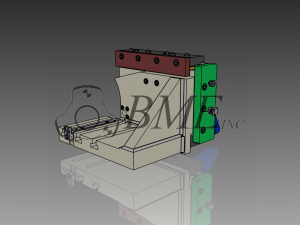

End Tool Stationary Milling

Mechanical drive from pickoff gear, sealed housing with lubrication points. Change Gear System allows for 30 different cutter speed combinations. Support Bushing available for small parts. Designed for spindle stop machines. Max. Speed = Machine Max. Speed. Interchangeable Base Plates for variety of machines.

End Tool Stationary Mill Catalog Page |

|

|